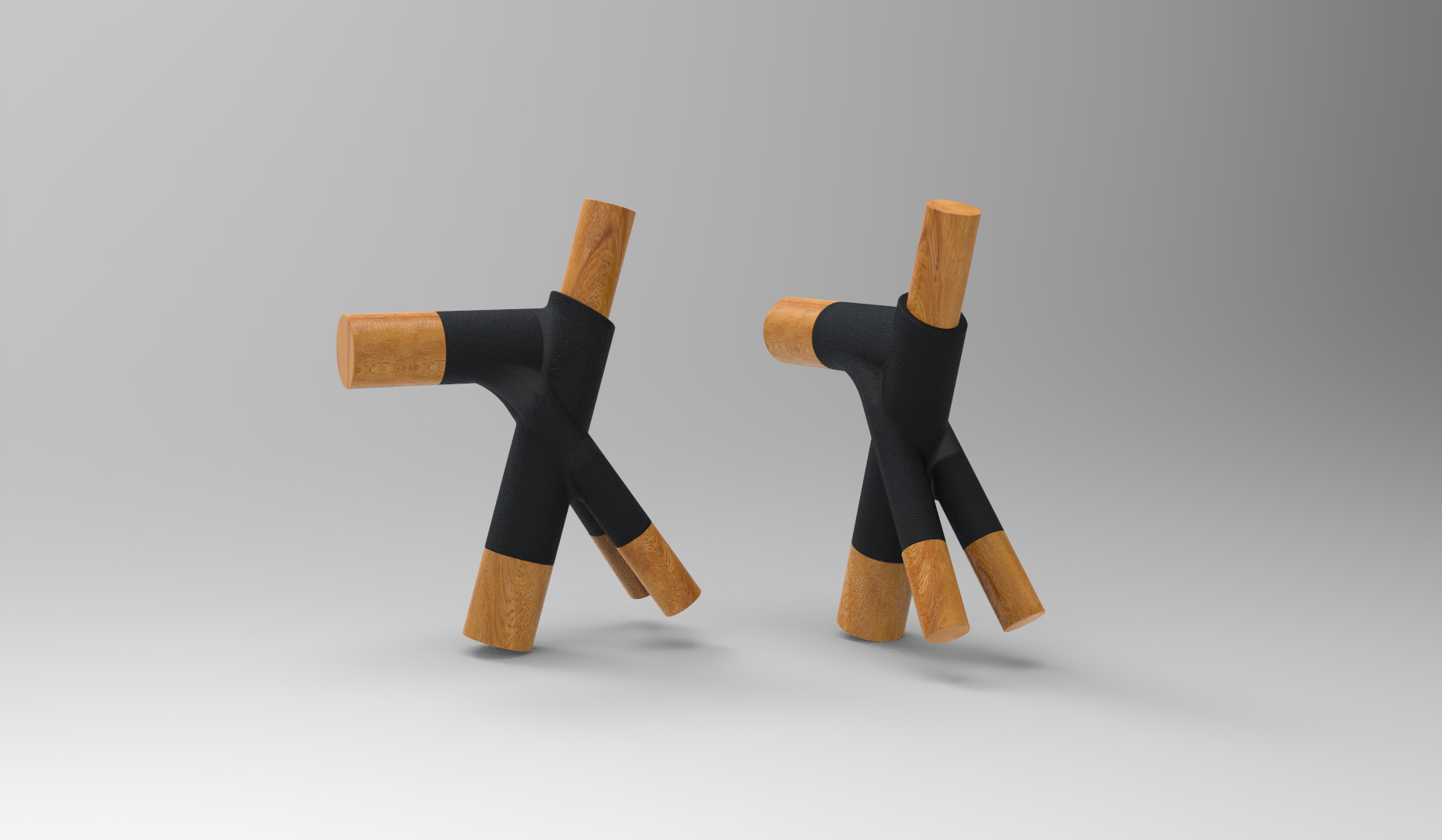

This day brought a mix of progress and setbacks. I made my first real attempt at designing a seat lug using surface modeling. While I did manage to create a shape, the result wasn’t good enough to meet my expectations. It was a valuable learning step, but I’ll need to refine my skills further before getting a usable design.

Printer Setup and Material Challenges

On the practical side, I prepared the printer for more consistent output. One issue came from the PA12CF spool: it’s slightly too wide for the CFS system to handle properly. As a workaround, I unwound a couple of meters from the spool. That helped a little, but it’s not a perfect fix. To really tackle print quality, I decided to invest in a new heater, which I ordered from Amazon. The goal is to stabilize the room temperature at around 70 °C — the recommended level for properly annealing these prints.

Small but Necessary Steps

The rest of the day went into office cleanup and reorganizing the workspace. Even though the first seat lug didn’t meet my standards, it still feels like I’m heading in the right direction. Every failed attempt sharpens the path toward something that will work.

Reflection

Progress often comes disguised as failure. Today’s lug didn’t succeed, but the lessons it taught will shape the next iteration.

“Each failed part is a step closer to the one that works.”