On the second day, I officially rolled up my sleeves and started working on the project itself. Until now it was mostly an idea with scattered sketches and notes, but today things started to take shape.

Collecting References

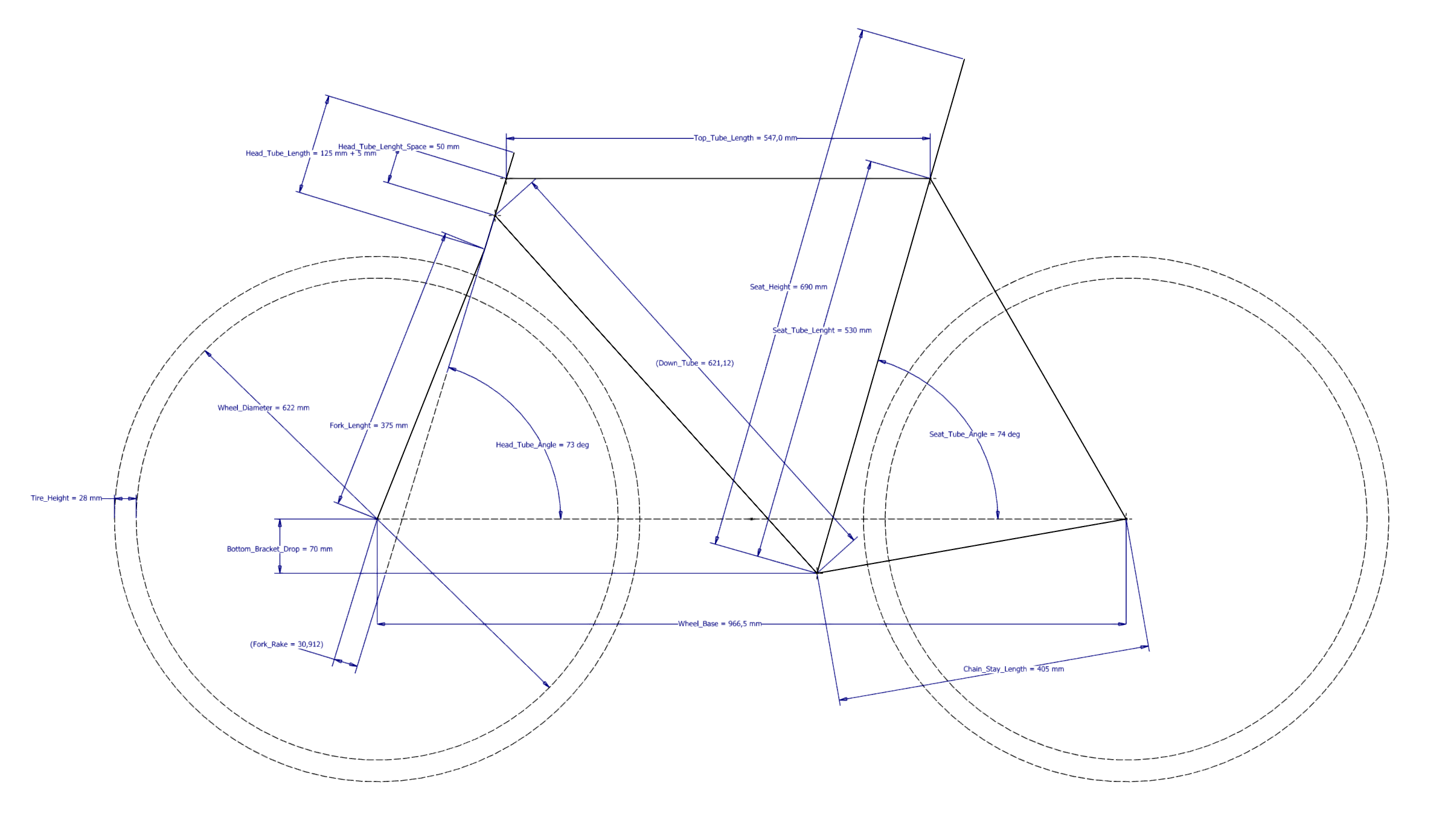

I kicked things off by looking up images of similar projects. It’s always helpful to see how others tackled the same kind of challenges — not to copy, but to get inspired and to understand what’s possible. Some pictures immediately sparked ideas, others helped me see constraints I’ll need to respect. Together, they gave me a rough mental map of the design space I’m working in.

Cleaning Up the Skeleton

The existing skeleton model also got some attention. I went through it, cleaned up the messier parts, and made sure it’s in a state where I can confidently build on top of it. Nothing flashy yet, but a clean foundation makes all the difference later.

Setting Up the Part Registry

The biggest milestone today was setting up the part registry. This might sound a bit boring compared to 3D models or actual bike parts, but it’s absolutely crucial for keeping the project sane. Here’s the idea:

- Every single part — whether it’s a bamboo tube, a 3D-printed lug, or even a small experimental piece — gets a unique six-digit number.

- The numbering starts at 000000 and can go all the way up to 999999. That means there’s room for a million parts if needed (not that I’ll ever get close, but it ensures no overlaps).

- Instead of stuffing names and details into the filename itself, all the metadata lives in a separate table. That table records what the part is, its material, dimensions, date created, and any extra notes. Why do it this way? Because file chaos kills projects. When you’re dealing with dozens or hundreds of parts, consistency is the only thing that keeps it manageable. If you ever need to swap out, search, or reference something months later, the registry makes sure nothing gets lost in translation. It’s the digital equivalent of labeling all the drawers in a workshop.

A Name in the Making

I also spent part of the day brainstorming possible names for the project. The list is growing — from playful ideas like OMG (Oh My Gear), to more adventurous ones like Atlas, to modern and tech-inspired names such as Velopen. I won’t reveal the direction just yet, but I’ll give a small hint: I’m looking for something that balances both sides of the project — the raw, natural vibe of bamboo on one hand, and the high-tech precision of 3D-printing on the other. A name that feels open, creative, and a little bit bold.

Reflection

Starting small doesn’t mean thinking small. Today was about laying down systems and structure — the kind of invisible work that makes future progress smoother. From here on, the project can only grow.

“Strong foundations make big ideas possible.”